The Importance of Recycling Rare Earth Materials in Electric Cars

When it comes to powering electric cars and their batteries, the use of rare and difficult-to-obtain materials poses a significant challenge. The reliance on rare earth elements (REEs) for magnets in motors raises concerns about economic security, especially with China dominating the market with 70-80% of the supply.

An initiative launched in 2019, titled Sustainable Recovery, Reprocessing and Reuse of Rare-Earth Magnets in a European Circular Economy, is dedicated to improving the efficiency of recycling these materials. With nineteen European partners involved, including ZF, efforts are being made to evaluate recycled REEs for new motors and develop designs that facilitate easier recycling of electric motors.

One of the main difficulties in recycling rare earth magnets is the challenge of separating them from the rotor and preventing the magnetized powder from sticking to other scrap materials. However, a new method called hydrogen processing of magnet scrap (HPMS), developed by Birmingham University, offers a solution by producing a non-magnetic, reusable powder without the need to remove magnets from the rotor.

By reprocessing the rare earth-rich powder into new magnets, this method significantly reduces the energy required compared to traditional manufacturing processes. ZF has conducted tests on motors made using HPMS and found that the performance of the recycled magnets is nearly identical to those made from virgin materials.

Another approach to reducing the reliance on virgin REEs is through the use of externally excited synchronous motors, which replace permanent magnets in the rotor with electromagnetic windings. Renault has adopted this technology in their vehicles since 2012, offering an alternative to traditional permanent magnet synchronous motors.

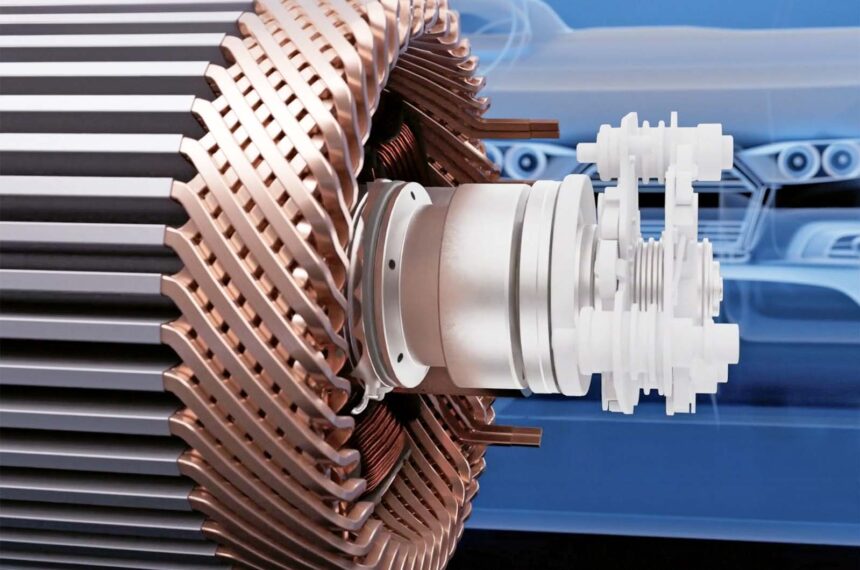

For those seeking a brushless alternative, ZF’s I2SM (in-rotor inductive excited synchronous motor) provides a solution by incorporating an inductive exciter inside the rotor shaft. This innovative design eliminates the need for brushes while maintaining high performance.