Tesla has recently unveiled its lithium-iron-phosphate (LFP) battery cell factory in Nevada, signaling that it is on the verge of commencing production. The company’s decision to establish its own battery cell manufacturing facility comes as a strategic move to reduce its reliance on Chinese manufacturers for its battery supply.

Currently, Tesla’s most affordable electric vehicles and energy storage products, including Megapacks and Powerwalls, utilize LFP cells sourced from Chinese manufacturers. However, the ongoing trade war between the US and China has created uncertainties regarding tariffs on imported battery cells.

In response to these challenges, Tesla had initially planned to build a small LFP battery factory in the US to circumvent the 25% tariffs imposed on Chinese battery cells. The company had acquired manufacturing equipment from CATL, one of its battery suppliers, to set up a facility for small-scale production in the US.

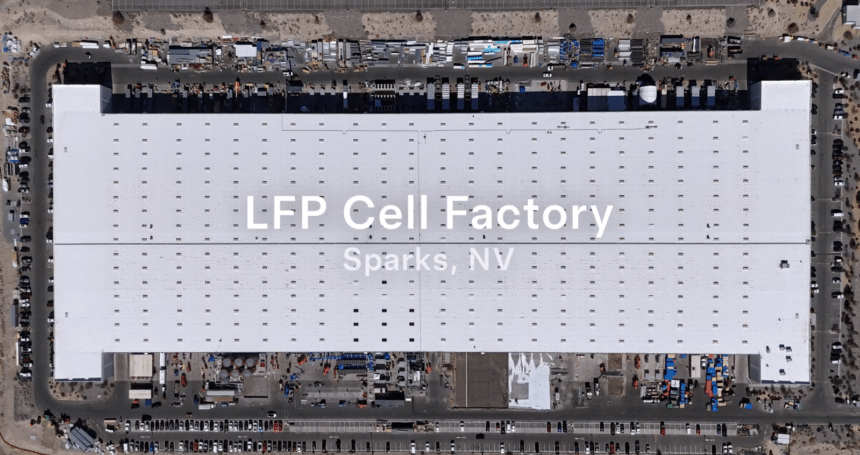

Tesla has now released images of the nearly completed factory in Nevada, showcasing its progress towards domestic battery cell production. The new facility is expected to produce around 10 GWh of LFP battery cells annually, primarily for use in Tesla’s Megapack energy storage systems manufactured in the US.

While Tesla’s move towards in-house battery cell production is a step in the right direction, it is unlikely to match the production scale of leading Chinese manufacturers like BYD and CATL in the LFP cell market. The shift towards domestic production will also help Tesla avoid potential tariffs on a portion of its US-produced Megapacks.

In a similar vein, Ford is also investing in its own LFP battery cell factory in Michigan with a significant production capacity of 35 GWh. Both Tesla’s and Ford’s initiatives predate the escalation of tariffs under the Trump administration, highlighting the companies’ proactive approach towards securing their battery supply chain.

Overall, the shift towards domestic battery cell production reflects a broader trend in the industry to localize manufacturing and reduce dependence on foreign suppliers. By establishing their own production facilities, companies like Tesla and Ford are not only mitigating tariff risks but also contributing to the growth of the domestic battery manufacturing sector.