CATL, a renowned battery manufacturer, has recently unveiled the Bedrock Chassis, a revolutionary skateboard chassis that has set a new standard in automotive safety. This cutting-edge chassis, designed to withstand extreme impacts, has been hailed as the world’s first ultra-safe chassis, promising to redefine safety in the automotive industry.

Unveiling Unprecedented Safety Performance

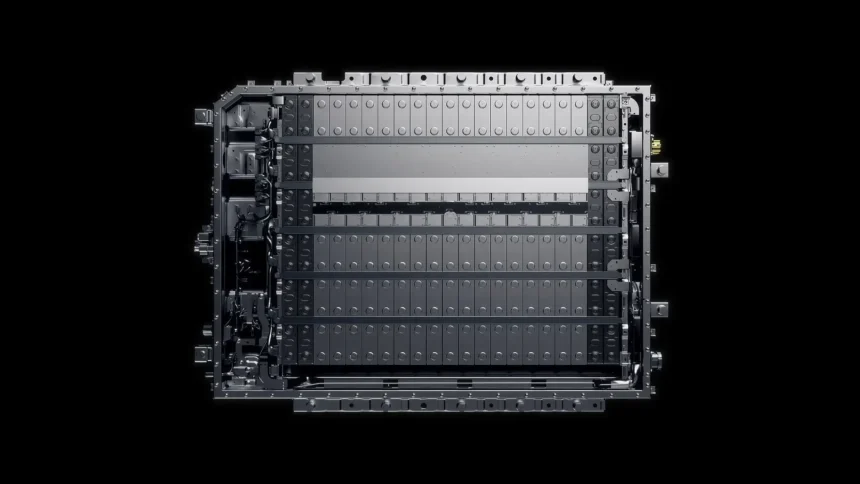

The Bedrock Chassis, developed with CATL’s innovative Cell-to-Chassis integration technology, integrates battery cells directly into the chassis, creating a unified structural design that enhances rigidity and impact resistance. This unique design allows the chassis to absorb up to 85% of collision energy, surpassing traditional chassis systems that typically absorb around 60%.

What truly sets the Bedrock Chassis apart is its exceptional performance in safety tests. The chassis successfully passed the world’s first 120 km/h frontal central pole impact test, a rigorous test that simulates high-speed collisions. Despite the intensity of the test, the chassis remained intact without catching fire, exploding, or experiencing thermal runaway. This remarkable feat challenges the conventional belief that gasoline-powered vehicles are inherently safer than new energy vehicles.

In comparison, the standard C-NCAP frontal crash test, conducted at 56 km/h, pales in comparison to the intensity of the 120 km/h test. The latter generates 21 times the pressure per unit area of a standard crash test, highlighting the remarkable resilience of the Bedrock Chassis in high-impact scenarios.

Three Technological Breakthroughs for Enhanced Safety

The Bedrock Chassis incorporates several cutting-edge technologies that offer unparalleled protection across various scenarios and speed ranges. These include:

1. Biomimetic Tortoise Shell Structure: Inspired by nature’s strongest defensive structures, this design integrates the body and energy unit framework to provide robust protection for the vehicle’s core components.

2. Aircraft Carrier-grade Arresting Structure: This structure disperses impact forces across multiple pathways, reducing the speed and depth of intrusions into the cabin during high-impact crashes.

3. Advanced Materials and Design: The chassis utilizes submarine-grade hot-formed steel (2000MPa) and aerospace-grade aluminum alloys (600MPa) to enhance rigidity and resilience against extreme forces.

Moreover, the chassis incorporates high-ductility energy-absorbing insulation films and NP technology for safe battery cell design. It also features a high-voltage disconnection system that can rapidly cut off electrical circuits and discharge residual high-voltage energy, setting a new industry standard for safety.

Opening a New Era of Customization and Speed in Vehicle Production

The launch of the Bedrock Chassis not only elevates vehicle safety standards but also accelerates the shift towards modular, personalized, and intelligent automotive design. CATL’s Cell-to-Chassis technology and decoupling of the chassis from the vehicle’s upper body enhance flexibility, enabling easier adaptation across different vehicle models.

With its scalable software and hardware architecture and standardized interfaces, the Bedrock Chassis empowers automakers to expedite vehicle development and production processes. This transformation reduces the traditional 36-month development cycle to just 12 to 18 months, fostering faster product iteration and customization in the automotive industry.

The chassis’ modular design facilitates “one chassis, multiple vehicle models,” optimizing development efficiency and cost-effectiveness. In terms of intelligence, the Bedrock Chassis supports L3 to L4 intelligent driving capabilities, incorporating mechanical decoupling, software decoupling, and EE decoupling technologies to enhance adaptability and collaboration with smart vehicle applications.

Partnerships and Future Innovation

At the launch event, AVATR, the first automaker to adopt the Bedrock Chassis, inked an agreement with CAIT-SH, CATL’s skateboard chassis division, to deepen their collaboration in enhancing travel safety and quality for users. This partnership marks a significant milestone in CATL’s mission to revolutionize transportation safety through continuous technological advancements.

Looking ahead, CATL remains committed to pushing the boundaries of automotive safety and collaborating with industry partners to establish a secure ecosystem for electric vehicle batteries and vehicles. By prioritizing user safety in every scenario, CATL aims to solidify its position as a leader in intelligent, customizable, and ultra-safe automotive solutions with the introduction of the Bedrock Chassis.