China’s Contemporary Amperex Technology Company Limited (CATL) has recently introduced its latest innovation, the ultra-safe Bedrock Chassis for battery electric vehicles (BEVs). This groundbreaking chassis is set to revolutionize the industry with its exceptional safety features and innovative design.

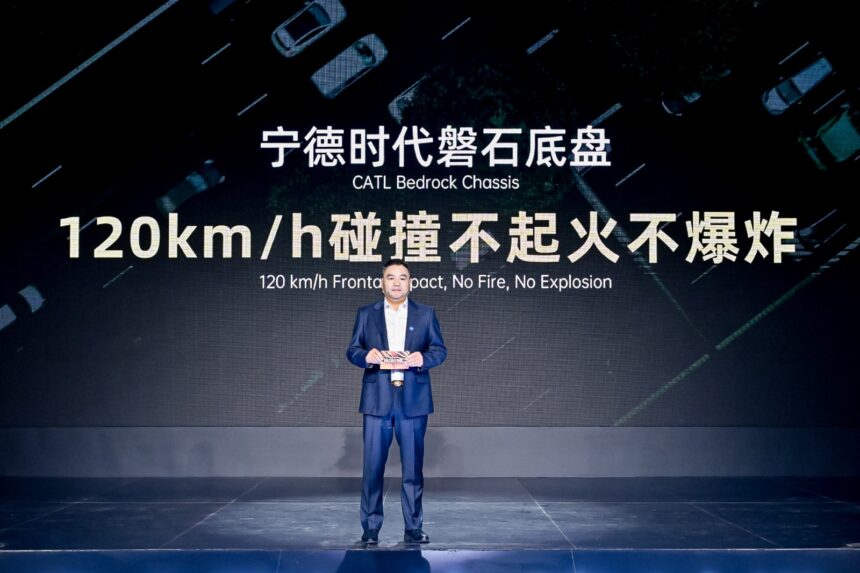

The Bedrock Chassis has been specifically engineered to withstand frontal impacts at speeds of up to 120 km/h without the risk of fire or explosion. CATL claims that this chassis sets a new standard for intelligent chassis safety, providing comprehensive protection across all scenarios and speed ranges.

Based on a battery-centered skateboard design, the Bedrock Chassis utilizes Cell-to-Chassis integration technology, which directly integrates the battery cells into the chassis for a shared structural design. This design enables the chassis to absorb 85% of collision energy compared to the standard BEV chassis, which typically absorbs around 60% of collision energy.

CATL has successfully passed the world’s first highest speed + strongest impact dual extreme safety test with the Bedrock Chassis. This achievement allows the chassis to pass the 120 km/h frontal central pole impact test without any incidents of fire, explosion, or thermal runaway. This redefines the benchmark for safety in the industry.

One of the key features of the Bedrock Chassis is its three-dimensional biomimetic tortoise shell structure, which integrates the body and energy unit framework to provide indestructible protection. This structure disperses impact forces across multiple pathways during a crash, gradually decelerating the vehicle and reducing the depth and speed at which obstacles intrude into the cabin.

Materials used in the construction of the Bedrock Chassis include submarine-grade hot-formed steel with a strength of 2000MPa, aerospace-grade aluminum alloy with a strength of 600MPa, and multiple barrier structures to enhance rigidity.

The chassis also incorporates an ultra-safe battery cell design known as NP technology and a high-ductility energy-absorbing insulation film. In the event of an impact, the high-voltage circuit disconnects within 0.01 seconds, and residual high-voltage energy is discharged within 0.2 seconds, setting a new industry record.

The first automaker to adopt CATL’s Bedrock Chassis will be Avatr Technology, a joint venture between Changan Automobile, Huawei, and CATL. This collaboration marks a significant milestone in the advancement of electric vehicle technology and safety standards.

Overall, CATL’s Bedrock Chassis represents a game-changing innovation in the EV industry, setting new standards for safety, performance, and design in battery electric vehicles. With its cutting-edge technology and exceptional safety features, the Bedrock Chassis is poised to reshape the future of electric mobility.