The heart of any electric car lies in its battery. This crucial component, although initially conceptualized in the 1800s, came to commercial fruition in 1991 with the introduction of lithium ion batteries by Sony. Despite the array of confusing names such as lithium-iron-phosphate, all these batteries are essentially lithium ion batteries with similar working principles and basic components.

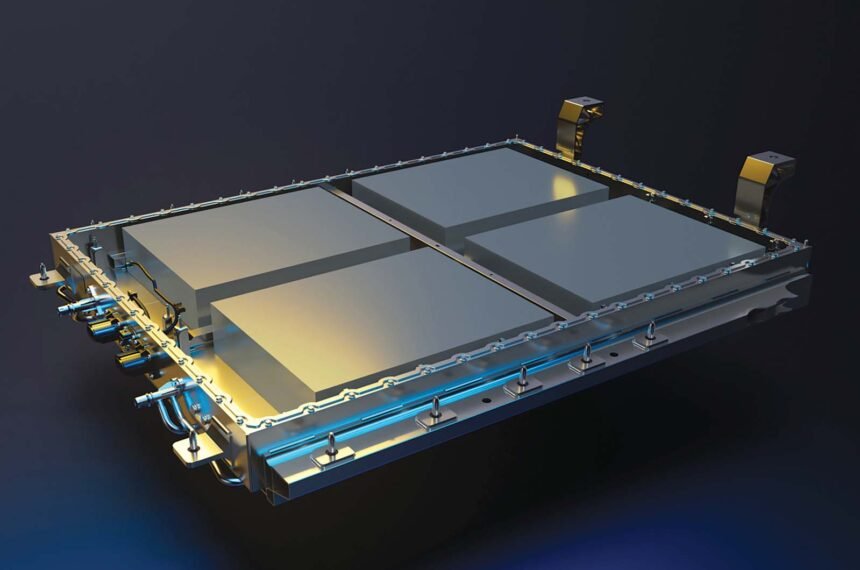

In essence, batteries are comprised of numerous battery cells, each generating a few volts and arranged in a casing to supply the necessary energy for an electric vehicle. These cells consist of positive cathodes, negative anodes, non-conductive separators, and liquid electrolytes. The cathode formulation, whether nickel-manganese-cobalt (NMC) or lithium-iron-phosphate (LFP), determines the characteristics of the battery, with the anode typically being carbon-based.

The production of these batteries involves mixing chemicals to create cathode paste, which is then applied to aluminum foil for NMC batteries and graphite paste on copper foil for the carbon anode. Different formulations yield varying battery properties, with NMC batteries offering higher energy storage for extended range, while LFP batteries are more cost-effective, stable, and environmentally friendly.

The charging and discharging process involves the movement of lithium ions between the cathode and anode through the electrolyte and separator. While sustainability considerations may favor batteries devoid of heavy metals like nickel and cobalt for their environmental friendliness, the day-to-day performance and efficiency of the battery ultimately determine the driving experience of the electric vehicle.

When selecting an electric vehicle, the focus should be on the overall performance and capabilities rather than the specific chemistry of the battery. Understanding the intricate workings of lithium ion batteries can provide insight into the technology driving the electric revolution and the sustainability of these innovative power sources.