Reducing carbon footprint and meeting EU battery regulations are key priorities for car and battery manufacturers. According to Schreiber, the battery is the biggest source of embedded carbon in an electric vehicle (EV), making it essential to use materials with lower emissions. Batteries made from recycled metals, such as CAM, can reduce embedded emissions by up to 74%.

Altilium partners with a third-party supplier for the initial stage of its recycling process. This involves shredding used batteries to extract essential metals in the form of black mass powder, which Altilium refines further.

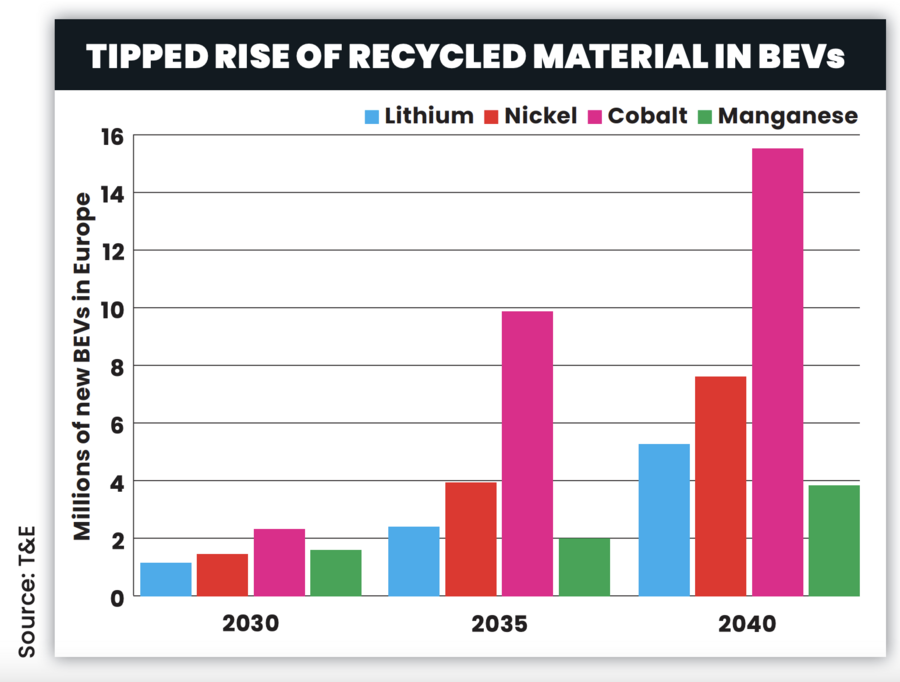

The majority of the feedstock consists of failed and damaged batteries rather than those reaching the end of their lifespan. While there is no precise data on the number of end-of-life batteries currently available, the industry anticipates a significant influx after 2030.

Advancing black mass refinement

Recyclus Group, the UK’s first large-scale lithium-ion battery recycling plant, recently sent 111 tonnes of black mass to Glencore, a global mining and recycling company. Similar to Altilium, Glencore will separate and refine the metals using its proprietary process.

“Since commencing large-scale recycling in 2023, our production of black mass has steadily increased,” stated Robin Brundle, co-founder and director of Recyclus Group. “This year, we aim to process 5000 tonnes of batteries with the capacity to handle up to 22,000 tonnes.”