Toyota’s Chemical Engineering Division is on a mission to achieve zero emissions throughout the life cycle of electric cars, starting from the extraction of raw materials to the recycling of components. The focus is not just on reducing emissions at the tailpipe, but on minimizing greenhouse gases released during the recycling process.

Currently, spent batteries are typically treated in incineration plants, where rare metals are collected after the combustion process. However, this method results in the loss of recyclable materials and the production of significant amounts of CO2. Toyota’s engineers have developed a new recycling system that aims to address these issues.

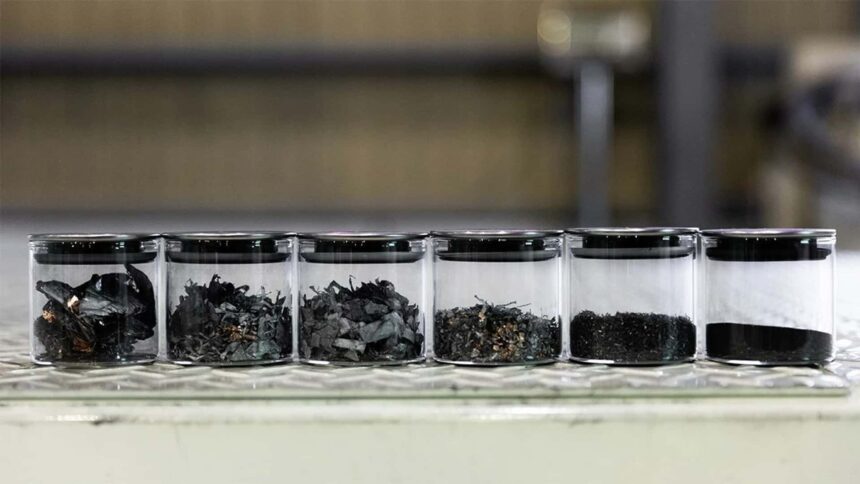

The innovative approach involves distilling and extracting the highly flammable electrolyte fluid from the batteries to eliminate the risk of fire during processing. The battery cells are then shredded, sorted, and reintegrated into the production process. The recovered parts consist of large pieces containing aluminum or iron, as well as a powder known as ‘black mass’ containing various rare metals. These recovered raw materials are further processed by partner companies to create new batteries.

This new method not only reduces the risk of fire and minimizes CO2 emissions but also maximizes the recovery of valuable materials from spent batteries. Additionally, it opens up new opportunities for creating a more sustainable circular economy in the automotive industry.

Toyota’s Chief Sustainability Officer, Yumi Otsuka, emphasizes the importance of considering the holistic life cycle of a car to reduce CO2 emissions and create new business opportunities. This approach aligns with the EU’s new regulations aimed at promoting the production of more batteries within the EU.

Overall, Toyota’s efforts to revolutionize battery recycling could have a significant impact on the industry, leading to a more sustainable and environmentally friendly approach to managing electric car batteries. The company’s commitment to innovation and sustainability is paving the way for a greener future in the automotive sector.