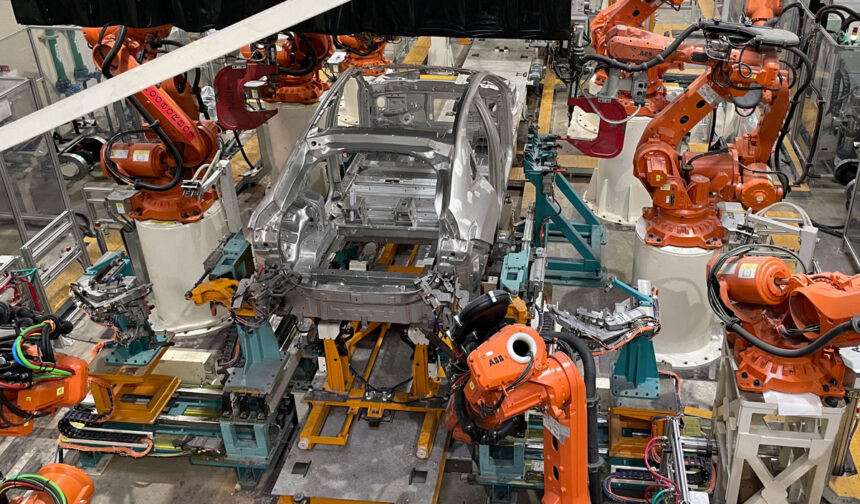

Nio is stepping up its automation game at the F2 plant with the introduction of more robotic quality control inspectors. The company’s founder, chairman, and CEO, William Li, recently shared images on Weibo showcasing robotic arms conducting quality checks on newly produced vehicles.

The F2 factory, located at NeoPark in Xinqiao, is Nio’s newest addition to its manufacturing facilities in Hefei, Anhui province. Last June, Nio confirmed the construction of a third factory, further expanding its production capacity.

Chinese electric vehicle manufacturers are known for their highly automated factories, with advanced robots playing a crucial role in the production process. One such example is UBTech Robotics’ Walker S robot, which was showcased in a video working on an assembly line at a Nio factory.

The video demonstrated the Walker S robot’s capabilities in performing quality inspections on various vehicle components, such as door locks, seat belts, and headlight covers. The use of humanoid robots in manufacturing has been gaining traction, with other companies like Huawei also testing and validating their own robotic solutions at Nio’s factories.

Kuavo, a humanoid robot developed by Leju Robotics and powered by Huawei’s HarmonyOS operating system, was tested at Nio’s facilities alongside Huawei’s Pangu large model. These efforts signify a shift towards integrating advanced robotics into industrial and home scenarios.

Nio’s commitment to automation and innovation in manufacturing is evident in its utilization of robotic quality inspectors at the F2 plant. With the automotive industry evolving rapidly, companies like Nio are leveraging cutting-edge technologies to enhance efficiency and quality in their production processes.