This hybrid model uses machine learning and physics to improve fatigue life prediction for lightweight magnesium alloys

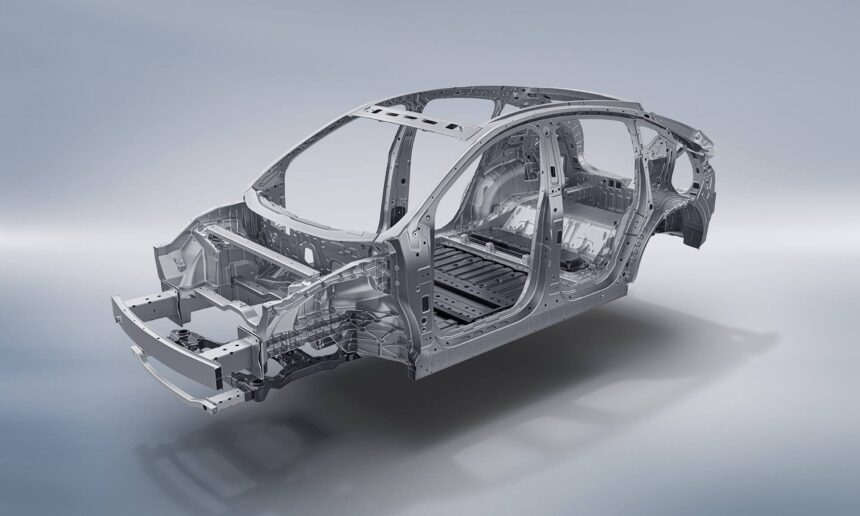

Magnesium alloys are increasingly popular in vehicle and aircraft design due to their strength, light weight, and ease of machining. Reducing weight is crucial because lighter vehicles need less power to move, saving energy and reducing emissions. However, since magnesium alloys behave differently under stress, predicting their ‘fatigue life’ has been challenging. Over time, parts made from these alloys can develop tiny cracks from the repeated stress during their use.

Until now, predicting exactly how and when these cracks will form has been difficult, as traditional methods involve empirical models that demand frequent adjustments for different loading conditions. This limitation makes them difficult to implement for industrial applications, where changing loads and directions are common.

A team of researchers led by Professor Taekyung Lee from Pusan National University, South Korea along with Mr. Jinyeong Yu, a Ph. D candidate set out to tackle this challenge. In their study published in Journal of Magnesium Alloys, the group integrated machine learning with energy-based physical modeling to improve prediction accuracy. The model works by using a combination of a neural network that analyzes complex patterns in stress and strain cycles, along with an energy-based physical model that provides a more holistic understanding of material behavior under cyclic loading.

The model was built using a large dataset of hysteresis loops—the stress-strain behaviors observed during repeated loading and unloading of the material—collected from low-cycle fatigue tests of the AZ31 magnesium alloy. “The neural network learns from these stress cycles which reveal how the metal stretches, bends, and returns to shape under load. We then use a physics-based model to ground the neural network in the physical laws of material science and to forecast when cracks may form,” explains Prof. Lee.

Instead of predicting fatigue life directly, the neural network estimates the hysteresis loops for the material under different conditions. By reconstructing these loops, it can more accurately assess how the material’s energy is dissipated during each cycle of loading and unloading, which is directly related to how quickly fatigue will accumulate. Then the physics-based model converts these stress cycle predictions into a reliable estimate of the number of cycles to failure, or the fatigue life of the alloy. “Because the machine learning component can continually adapt as it learns from the loop data, this method is more flexible across multiple loading directions and conditions, removing the need for manual parameter adjustments,” adds Prof. Lee.

With the advent of this new approach, manufacturers may soon benefit from greater predictive reliability when working with magnesium alloys, enabling safer, lighter, and more cost-effective designs in high-stakes environments. The model offers a more streamlined and accurate approach to the fatigue life prediction of magnesium alloys that could lead to enhanced safety and longevity of critical components in real-world applications.