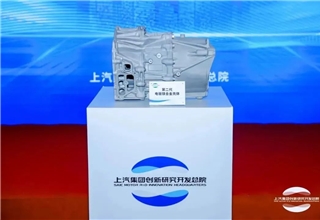

SAIC Motor Unveils Second-Generation Magnesium Alloy Case for Electric Drive System

SAIC Motor’s R&D Innovation Headquarters recently introduced its self-developed second-generation magnesium alloy case for electric drive assembly, marking a significant milestone in the automotive industry. This innovative product is the world’s first mass-produced magnesium alloy case for electric drive systems to utilize a semi-solid processing technique. Made from AZ91D magnesium alloy, the case weighs just 13.7 kg, showcasing its lightweight and high-performance properties.

Mr. Wang Jian, the Executive Director of the Drive System Hardware Department at SAIC Motor’s R&D Innovation Headquarters, highlighted the importance of this new product. He emphasized that the introduction of the second-generation magnesium alloy case demonstrates SAIC’s dedication to developing environmentally friendly solutions that prioritize lightweight materials. The semi-solid processing technique employed in the manufacturing process enhances the material’s strength, ductility, and corrosion resistance, making it ideal for large-scale production in the new energy vehicle (NEV) sector.

The volume production of the second-generation magnesium alloy case represents a significant advancement in the use of magnesium alloy as a lightweight material in electric drive systems. By incorporating semi-solid technology, SAIC Motor is not only enhancing vehicle lightweighting but also setting new standards for sustainable manufacturing practices. This innovation is expected to accelerate the lightweighting process of NEVs and contribute to global efforts to achieve carbon neutrality.

In addition to its environmental benefits, the second-generation magnesium alloy case is poised to drive the development of the entire magnesium alloy industry chain and solidify China’s position as a leader in magnesium material research and applications. The utilization of the semi-solid processing technique improves the material’s flowability, resulting in uniform and fine spherical phases that enhance casting quality. This technique also enhances the mechanical properties, elongation, and density of the castings while reducing energy consumption during manufacturing.

SAIC Motor’s commitment to innovation in lightweight materials dates back to the introduction of the IM L7, the first model from its premium EV brand, IM Motors, in 2022. The electric drive system of the IM L7 was encased in a magnesium alloy case, paving the way for the widespread adoption of magnesium alloys in the automotive industry.

Overall, SAIC Motor’s second-generation magnesium alloy case represents a significant breakthrough in the development of lightweight materials for electric drive systems. By incorporating advanced manufacturing techniques and prioritizing sustainability, SAIC Motor is driving the automotive industry towards a more environmentally friendly and efficient future.