Schaeffler Achieves Milestone in Electrification Business with Production Launch of Two New E-Drive Products

Schaeffler, a leading supplier in the automotive industry, has recently announced a significant milestone in its electrification business with the start of production for two innovative e-drive projects at its Tianjin facility. The new products include a 900V silicon carbide power module inverter brick and a 48V P2 transmission-integrated electric motor, marking a significant step forward in the company’s commitment to diversified drive technologies.

The mass production launch not only showcases Schaeffler’s dedication to advancing e-mobility solutions but also highlights the synergies resulting from its recent integration efforts. Thomas Stierle, CEO of Schaeffler’s E-Mobility division, emphasized the importance of these new products in meeting the evolving market demands for electrified vehicles. He stated, “As the global wave of electrification accelerates, Schaeffler will continue to deepen its presence in both China and international markets, delivering solutions that combine performance advantages with cost efficiency.”

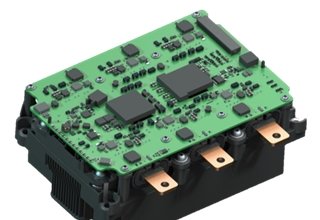

The first product, the 900V silicon carbide power module inverter brick, features an innovative design that combines a 900V power module with bus capacitors and boost capacitors through integrated molding. This design significantly enhances power density in the e-drive system, offering advantages such as smaller size, higher output, and lower cost. With an output current capacity of ≥650Arms and peak efficiency of 99.5%, this module sets a new industry benchmark, translating into benefits such as faster acceleration response, extended driving range, reduced energy losses, and improved thermal efficiency for electric vehicles.

The second product, the 48V P2 transmission-integrated electric motor, is a collaborative effort between Schaeffler’s R&D teams in Germany, Shanghai, and Tianjin. This motor features a 48V controller with PCB-embedded chip technology, reducing PCB footprint and enhancing system efficiency. Schaeffler’s ability to achieve mass production of low-voltage PCB-embedded chips sets them apart in the industry, showcasing their commitment to innovation and customer support.

Overall, Schaeffler’s production launch of these two new e-drive products demonstrates their dedication to advancing electrification technologies and meeting the evolving needs of the automotive market. By leveraging their expertise in diverse drive technologies and local manufacturing capabilities, Schaeffler is well-positioned to support customers in their electrification projects and drive the future of sustainable mobility.