Torque wrenches are an essential tool for anyone working on cars or machinery that requires precise fastening. These tools are responsible for tightening nuts and bolts to specific measurements, ensuring that components are assembled correctly and securely. While the concept of a torque wrench may seem simple on the surface, the inner workings of these tools are actually quite fascinating.

A recent video from the Deconstructed YouTube channel delves into the mechanics of a ratcheting click-type torque wrench, which is a common type of torque wrench found in many toolboxes. Unlike digital torque wrenches that require batteries, this analog torque wrench operates purely on mechanical components.

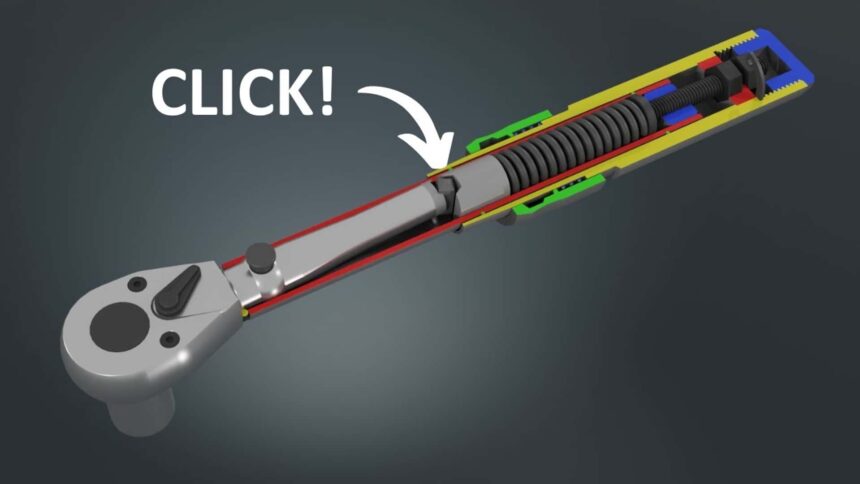

At the top of the torque wrench is a standard ratcheting socket attachment point, which is connected to the wrench body via a central pin. This design allows the ratcheting piece to pivot within the wrench cylinder. A spring located at the bottom of the torque wrench applies tension to a metal cube known as a pivot block, which interacts with the ratcheting mechanism.

The tension in the spring determines when the pivot block will shift, producing the audible “click” that indicates the desired torque has been reached. Adjusting the torque setting on the wrench handle changes the tension in the spring, altering the amount of force required to trigger the pivot block to shift.

Proper storage of a torque wrench is crucial to maintaining its accuracy and longevity. Storing the wrench at the lowest setting helps to relieve the spring of excess pressure, preventing potential issues such as “creep,” which is the gradual deformation of the spring over time.

Understanding the mechanics of a torque wrench not only enhances one’s appreciation for this essential tool but also underscores the importance of proper usage and maintenance. By keeping your torque wrench in good condition, you can ensure that your fasteners are tightened correctly and your projects are completed with precision.