Hyundai Mobis, a key component manufacturing affiliate of Hyundai Motor Group, has recently unveiled a groundbreaking battery cell cooling material designed to prevent electric vehicle (EV) batteries from overheating during ultra-fast charging. This development comes in light of a significant EV battery fire incident in South Korea, which affected over 100 vehicles in an apartment car park back in August.

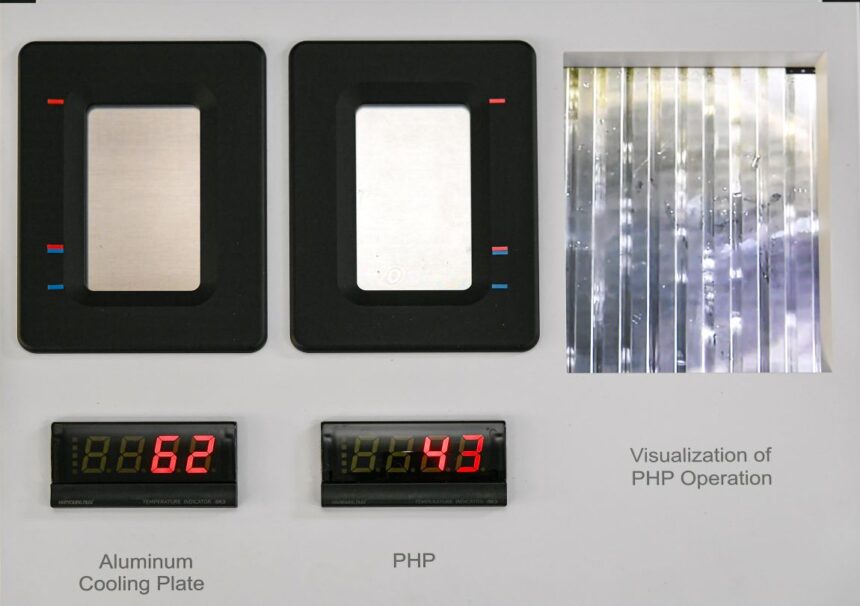

The new cooling material, known as a ‘Pulsating Heat Pipe’ (PHP), is made of aluminum alloy and refrigerant. It is strategically placed between battery cells to effectively reduce the internal battery temperature that tends to spike during rapid charging. Heat pipes, which are metal tube-shaped heat conductors, are renowned for enhancing heat transfer efficiency between two objects. They are commonly utilized for cooling electronic devices such as computer CPUs and smartphones.

Hyundai Mobis’ PHPs utilize vibration to improve internal refrigerant circulation, leading to more efficient heat diffusion and minimal performance degradation even under high-speed vehicle movement. The company claims that its PHPs offer over ten times the heat transfer performance compared to standard aluminum heat pipes, swiftly transferring heat away from overheated battery cells.

Moreover, Hyundai Mobis asserts that its PHPs play a significant role in reducing EV charging times by implementing a more stable thermal management system. The company aims to establish itself as a leader in battery cooling technology and enhance its competitiveness in the future mobility market.

In terms of battery pack design, EVs typically incorporate integrated battery management systems (BMS) that include cooling fans and electronic devices to manage multiple battery modules. The Battery Management Assembly (BMA), which directly generates electrical energy, consists of multiple battery cells stacked together. Optimizing the cooling structure to prevent battery cell overheating is crucial, and Hyundai Mobis has successfully integrated PHPs between each battery cell to ensure efficient heat transfer to cooling blocks, thereby maintaining stable internal temperatures at the module level.

This innovative battery cooling technology not only enhances the safety and performance of EV batteries but also contributes to reducing charging times, thus advancing the future of electric mobility. Hyundai Mobis continues to innovate and strengthen its battery safety solutions to meet the evolving needs of the electric vehicle market.