Tinius Olsen Supports London South Bank University School of Engineering in Testing Insect-Inspired One-Way Hinge

The London South Bank University School of Engineering has been conducting groundbreaking research with the support of Tinius Olsen to test a unique one-way hinge inspired by the wings of insects. This new discovery, derived from the wings of a flying beetle, offers insights into how wings change shape during flight using a bell-shaped structure that is compliant in one direction and significantly stiffer in the opposite direction.

The results of the study have revealed that this structure functions as an effective one-way hinge, utilizing a single material without adding any extra mass. The potential applications of this insect-inspired hinge are vast, including easily assemblable modular designs, adaptive airless tires, and metamaterials with zero Poisson’s ratio. This suggests that the structure has biomimetic applications across a wide range of sizes.

Hamed Rajabi, a lecturer in Mechanical Engineering and Design at the London South Bank University School of Engineering, explains, “Insect wings demonstrate remarkable automatic shape morphing abilities, both in nature and technology, the mechanisms of which are not fully understood. These wings are deformable airfoils that undergo complex interactions between their structural components.”

He continues, “The hinge found in insect wings plays a crucial role in enabling automatic and asymmetric deformations during flight, controlling the precise folding and unfolding patterns. The unique double membrane hinge identified in the hind-wing membrane of the beetle Pachnoda Marginata showcases reversible thin-plate buckling, allowing it to function as a one-way hinge.”

Through computational simulations and physical modeling, the researchers confirmed that the double-layer membrane hinge can act as an effective one-way hinge, offering stiffness in tension and upward bending while remaining flexible in compression and downward bending. By adjusting the design parameters, the properties of the hinge can be tuned over a wide range, providing a versatile design space for various applications.

The potential applications of this discovery are vast. The researchers have already developed a modular design that can be easily assembled and disassembled, as well as an innovative airless tire design with wide-ranging applications. Additionally, they have created a meta material with zero Poisson’s ratio, allowing for control over compressive behavior using the unique hinge joints.

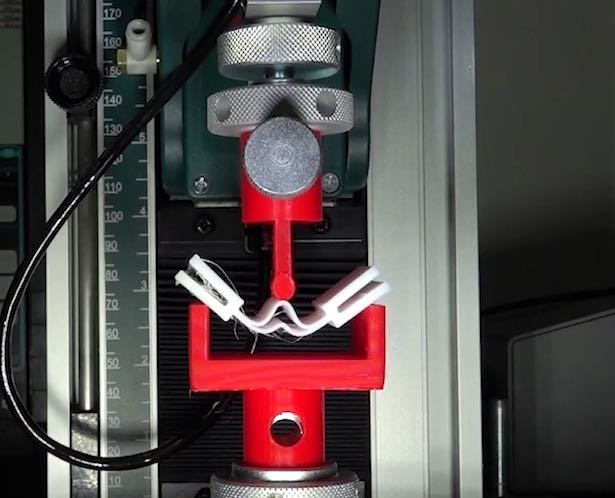

Tinius Olsen’s support in this project was instrumental, providing a 1ST UTM equipped with a 500N load cell for tension and compression testing. The collaboration between Tinius Olsen and the research team led to the successful execution of the study, with the company’s expertise and equipment playing a crucial role in the project’s success.

Hamed expresses his gratitude, stating, “The support from Tinius Olsen with this project was incredible. Their assistance in selecting the right testing machine, load cell, and accessories, as well as providing training on the 1ST and Horizon software, was invaluable. We couldn’t have achieved our research goals without their input.”

For more information on this groundbreaking research, visit the Tinius Olsen website.