Shanghai-based Rapow Technology Celebrates Milestone in Electric Drive Assembly Production

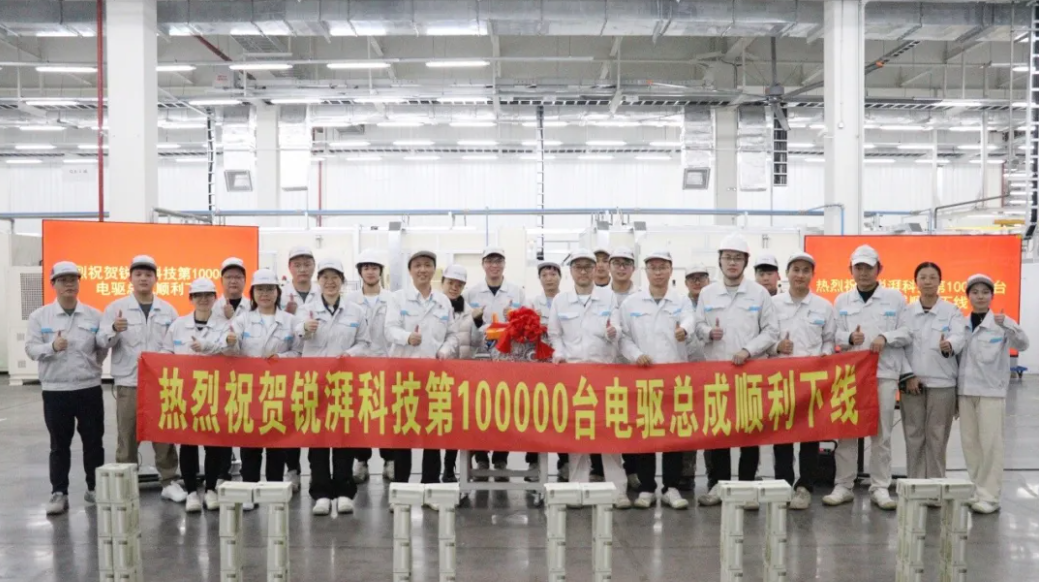

Shanghai (Gasgoo)- On December 24, Rapow Technology Co., Ltd. marked a significant achievement as they celebrated the production of their 100,000th electric drive assembly at their intelligent ecological electric drive factory. This milestone was shared in a post on Rapow Technology’s WeChat account.

Photo credit: Rapow Technology

Rapow Technology, a joint venture between GAC Group, GAC AION, and GAC Trumpchi, commenced the construction of their intelligent ecological electric drive factory on December 29, 2022. The factory officially started operations on January 30, 2024. This achievement signifies GAC AION’s establishment of in-house development and production capabilities for the core components of new energy vehicles, including batteries, electric motors, and electronic control systems.

Spanning 104,000 square meters with a total investment of 2.16 billion yuan, the plant focuses on the in-house research and development and industrialization of the integrated drive unit (IDU) electric drive system and electronic control units. This integrated approach covers all aspects from R&D to manufacturing, sales, and service. The factory is projected to produce 400,000 sets of IDU electric drive systems and 100,000 sets of electric motors and electronic control systems for GMC hybrid electromechanical coupling systems annually.

Rapow Technology has developed various electric drive systems, including the M25 Super Electric Drive, M58 Supercar Electric Drive, M15 N-in-one Electric Drive, and M10 N-in-1 Electric Drive. These systems are utilized in models such as the HYPTEC HT, HYPTEC HL, HYPTEC SSR, second-generation AION V, AION RT, and AION UT, covering A-, B-, and C-segment battery electric vehicles (BEVs) and plug-in hybrid vehicles (PHEVs).

Additionally, GAC AION’s Inpow Battery Intelligent Ecological Plant, completed and operational since December 12, 2023, boasts a production capacity of 6GWh per year in its first phase, with plans to expand to 36GWh. This facility supports the installation of batteries for 600,000 NEVs annually and also manufactures sodium-ion and solid-state batteries.